Oil is one of the important resources for the development of science and technology in China, and the level of oil recovery has also become a concern of China’s industry. The water content of petroleum in our country has always been high. How to reduce the water content has also become a major problem in the industry. Tertiary oil recovery technology using polymer as carrier is an effective measure to solve this problem. This method effectively improves the salt resistance of oil and reduces environmental pollution. Therefore, the innovative development of new polymers is the key to promote China’s oil exploration technology.

Keywords: polymer, tertiary oil recovery technology, development process, main research direction

At present, China’s oil has a high water content, and its dependence on foreign oil is also increasing. Oil occupies a considerable position in China. Therefore, we must ensure that oil can increase production on the basis of stable production and safe exploitation. It is the most important problem to effectively reduce the water content of oil, and the tertiary oil recovery using polymer as the carrier is one of the most effective measures to solve this problem. In this process, the main polymer is polyacrylamide, which can cause instability, environmental pollution, poor salt resistance and other factors, so these factors have caused technical problems that must be solved on the road of promotion. In order to promote the development of oil industry, the research on new polymers has become the key technology.

1、 Development process of tertiary oil recovery technology

Tertiary oil recovery technology has experienced three large-scale development changes. The first development was from 1950 to 1969. Heavy oil was widely used in the petroleum industry to achieve steam oil displacement technology, so heavy oil was widely used in the world. The second development was from 1971 to 1980. At that time, steam flooding was the main way, but tertiary oil recovery with chemical flooding was developed rapidly. However, the development of chemical flooding at that time was restricted by many uncertain factors, such as high cost, heavy pollution, etc. The third development started in 1990, and the miscible gas injection technology has been widely developed in China. This technology has the advantages of low use cost, wide application range, and can meet the requirements of environmental protection.

2、 New polymer tertiary oil recovery technology

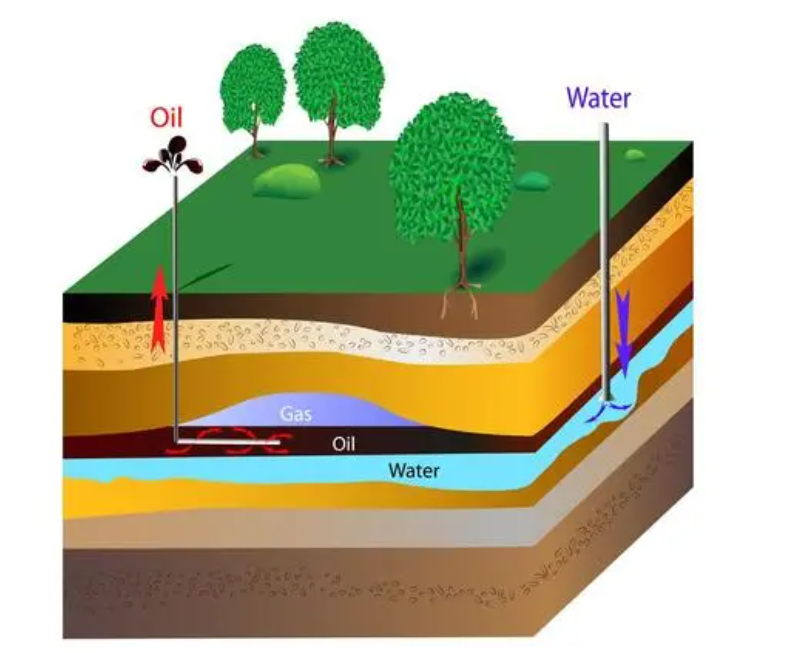

This technology collects oil fluid in three times. Primary oil recovery refers to the reservoir energy in the process of oil exploitation; The process of secondary oil recovery is to fill the reservoir with flowing energy, usually to supplement gas and water to the reservoir; Tertiary oil recovery uses chemicals to change the mutual performance of gas, water, oil and rock. Among the three oil recovery technologies, the third oil recovery technology is the most recognized and widely used today. This technology has more efficient recovery than the other two, can effectively reduce the water cut of the oilfield, and is the main measure to improve the oil quality in China. New polymers exist in comb molecular structure, which can improve the salt resistance of polymer molecules and greatly enhance the oil recovery. This new polymer has been widely used in major oilfields in China, and the effect is very significant, which has been proved in practice. Compared with conventional polyacrylamide, this new polymer molecule not only greatly reduces the use cost, but also can protect the environment and increase the oil recovery rate by two percent, greatly improving the oil recovery rate.

3、 Main research directions of tertiary oil recovery

First, in today’s oil field, surfactant with good oil displacement effect and low cost is the research guideline at this stage in the development of ternary composite system oil displacement technology. In addition, the selection of surfactant is studied in order to effectively reduce the cost of surfactant in ternary coincidence system. At present, the research focus of the petroleum industry is to reduce the chromatographic separation effect, and feasible and effective solutions have been proposed in various related oilfields, which provides a strong basis for the large parallel distance formula.

Second, to improve oil recovery, foam composite flooding is also an efficient technology. This technology not only integrates the advantages of thermal oil recovery, but also has the advantages of foam oil displacement, and also has the oil displacement effect of nitrogen and carbon dioxide, greatly improving the oil displacement effect.

This technology can effectively penetrate into the small gaps and holes that cannot be accessed by the ternary composite system to remove residual oil stains. The relevant experiments show that the oil recovery factor is effectively improved by foam flooding. After polymer injection, with the increasing temperature, foam composite flooding also improves the oil recovery. Under high temperature conditions, the oil recovery can reach 16%.

Third, in recent years, microbial oil displacement has developed rapidly in tertiary oil recovery technology, and almost all major oilfields have carried out relevant research on microbial oil displacement and oil recovery. There are more than 20 microbial oil displacement test sites in China. However, the current technology is not perfect, and some technical problems still need to be solved, such as the research on screening microbial colonies in the natural environment.

4、 Problems

The use of polymers in oil fields can greatly improve the oil recovery rate and thus bring great economic profits, but nothing in the world is perfect. The following are some problems in the practical application of polymers:

(1) Wellhead blockage

The important factor to ensure oil recovery is polymer, which can greatly reduce the water content of oil. Due to the interference of various factors, when the injection pressure of some polymers rises and approaches the fracture pressure, their pressure values do not meet the requirements, and when the injection volume is reduced, obvious polymer plugging occurs at the wellhead, which affects the efficiency of oil production.

(2) Injection allocation with sewage

The purpose is to reduce the use cost of polymer flooding and reduce the use of clean water for polymer flooding. Up to now, preliminary progress has been made in the research of polymer injection with oily sewage. The first method is to directly use oily sewage to dilute salt resistant polymer. Before dilution, bacterial impurities must be removed to ensure that the viscosity of polymer will not be changed. The second method is to pretreat the oily sewage to make its water quality reach low salinity clear water, and then inject it into the polymer. However, the current research does not have a deep understanding of the viscosity mechanism affecting the polymer, and the process of configuring polymer with oily sewage needs further optimization and improvement.

5、 Conclusion

The tertiary exploration technology integrates the high and new technologies in physics, chemistry and biology to continuously improve the oil exploration technology. In the field of petroleum industry, the tertiary exploitation technology based on polymer has reached the industrialized and large-scale use, which can provide powerful technical means for China’s petroleum exploitation. However, with the strengthening of technical means, some of the problems that come along really give us a headache. The two problems mentioned in the article are just one of many of them. Therefore, on the road of three times of mining research and development, we cannot relax at any time. We should strengthen the efforts of scientific research to tackle key problems, and solve the problems in mining technology better and more efficiently.

Post time: Oct-19-2022