Coking Wastewater Modifier

Coking Wastewater Modifier

Description:

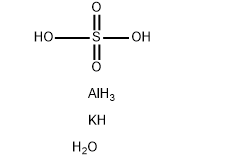

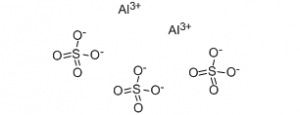

JD-T01 coking wastewater modifier is a new type of wastewater modifier specially developed for high oil content, high COD, high degree of emulsification, and poor water quality in coking wastewater from refineries. The product can be electrolyzed in water to generate electric charge, thereby neutralizing the electrical properties of the surface of the dissolved oil and suspended solids in the sewage, so that the suspended solids that have lost their electrical properties are coalesced under the action of the multi branched polymer polymer bridge. Sinking, so as to achieve the purpose of demulsification, aggregation, separation, oil removal, and clarification of water quality. Products are widely used in the purification and treatment of high oily wastewater from refinery coking plants.

Features:

• It has excellent bridging flocculation ability, can quickly gather the oil droplets dissolved in the water, and make the oil and water separate quickly.

• It can play a good role in electric neutralization, bridging, demulsification and flocculation with the negatively charged oil-in water emulsion.

•It has the characteristics of fast action speed, good demulsification and aggregation, fast sedimentation, and remarkable dehydration and water purification effect.

Instructions:

Mainly used in the treatment of high-oily wastewater in oil refineries. Dosing of metering pump. Use temperature control of 30-80℃ to have the best effect, and the specific temperature depends on the site temperature. The dosage of the product varies from 100- 500PPM, which is determined according to the oil content of the sewage and the indoor evaluation test. The top of the coking tower or the metering pump in front of the oil-water separation tank is continuously added or intermittently added according to the site conditions. The specific dosing can be guided by our technicians

Packaging, storage and safety:

• Packed in 25 liters, 200 liters plastic drums or 1000 liters ton drums.

• During transportation, load and unload with care to avoid damage to the packaging and spillage.

•Non-toxic and weakly corrosive liquid, stay away from alkaline substances and strong oxidants, prevent exposure to the sun, and the shelf life is one year.

Write your message here and send it to us