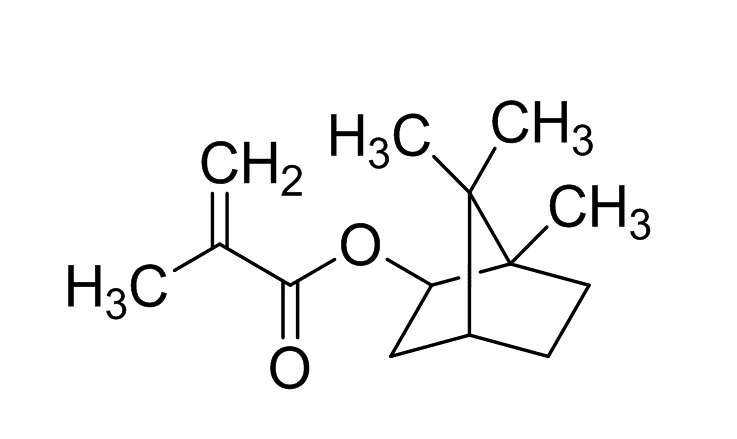

Isobornyl methcrylate (IBOMA)

Isobornyl methcrylate (IBOMA)

Description :IBOA, due to its special structure and properties, is attracting people’s interest and attention in the research and application as a novel acrylic monomers in recent years. IBOA can be used to synthesize high performance polymer materials continue to meeting modern technology and environmental requirements. It has a good application prospect In the high-solids coatings, automotive coatings, light-curing coatings, optical coatings, the modified powder coatings, etc.

Characteristics :

1.Excellent UV resistance, water resistance and chemical resistance;

2.Low viscosity, Improved compatibility with other resins and solvents;

3.High-boiling, low-volatile;

4.High reactivity;

5.High hardness, low shrinkage.

Application :

1.IBOA make polymers have excellent properties, such as high gloss, distinctness of image, abrasion resistance and weather resistance, chemical resistance. Used for high-grade paint formulations;

2.Used for heat-resistant organic sheets, fiber, adhesives, printing inks containing reagent, modified powder coating, cleaning coatings, high solids low viscosity coatings; Reactive diluent, modified resin monomer to increase toughness, and To improve the dispersibility of the resin to the pigment;

3.In the acrylic resin formulations, can effectively reduce the viscosity of the polymer solution (generally the amount of the effect will be more obvious in the five percent to ten percent or so);

4.IBOA suitable for the manufacture of high Tg thermoplastic acrylic resin, which product has high hardness, high alcohol resistance, heat resistance, good flexibility adhesion and moisture resistance, weather resistance.

5.IBOA is a new acrylate monomer with a specific structure, used the production of thin-film coating of soft plastic, such as PET, PE, PP, etc. And a decorative protective coating of PE, PP, PC and other plastic parts.

General hints:Combustible! Polymerization may be initiated by contamination with peroxides, azo compounds, heavy metal ions, tert. Amines, S compounds. Polymerization is also induced by light. Atomospheric oxygen saturation in the monomer is necessary for stability. Storage temperatures should not exceed 35℃.

Transportation and storage:

1.Avoid shine rain and high temperature in transportation;

2.Store the products in cool, shady and ventilated conditions, keep far away from fire;

3.12 months from date of delivery at a maximum storage temperature of 30℃.